उत्पाद विवरण:

मूल्य और मात्रा

- 1

व्यापार सूचना

- प्रति महीने

- महीने

उत्पाद वर्णन

A polyester resin plant is a facility that manufactures polyester resin, a versatile liquid material used in various applications, including:

Composite materials: Polyester resin is a key component of fiberglass composites, commonly used in boat hulls, building panels, and automotive parts.

Coatings: Polyester resins are used in paints, varnishes, and gelcoats for their durability, gloss, and weather resistance.

Adhesives: Polyester resins can be used as adhesives for bonding various materials, such as wood, metal, and concrete.

Casting: Polyester resins can be used for casting decorative objects, countertops, and other functional parts.

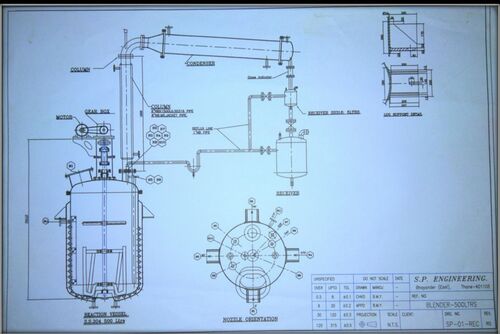

The exact configuration of a polyester resin plant can vary depending on the desired production capacity, resin type, and level of automation. However, a typical plant will involve the following key stages:

Raw material storage: This includes tanks for storing the liquid monomers (such as maleic anhydride and propylene glycol) and other chemicals used in the resin production process.

Esterification: The monomers are reacted in heated kettles with a catalyst to form the polyester resin precursor.

Blending: The resin precursor is blended with additives and solvents to achieve the desired properties, such as viscosity, flexibility, and curing speed.

Filtration and storage: The finished resin is filtered to remove impurities and then stored in tanks until needed.

Packaging: The resin is packaged in drums, totes, or bulk containers for shipment to customers.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+